GAS

Cameron’s WKM brand is recognized throughout the world for durable, reliable and flexible valves built for many challenging situations. The WKM product line offers a broad line of valves including ANSI gate valves, DynaSeal ball valves and DynaCentric butterfly valves, all built to standards for demanding applications.

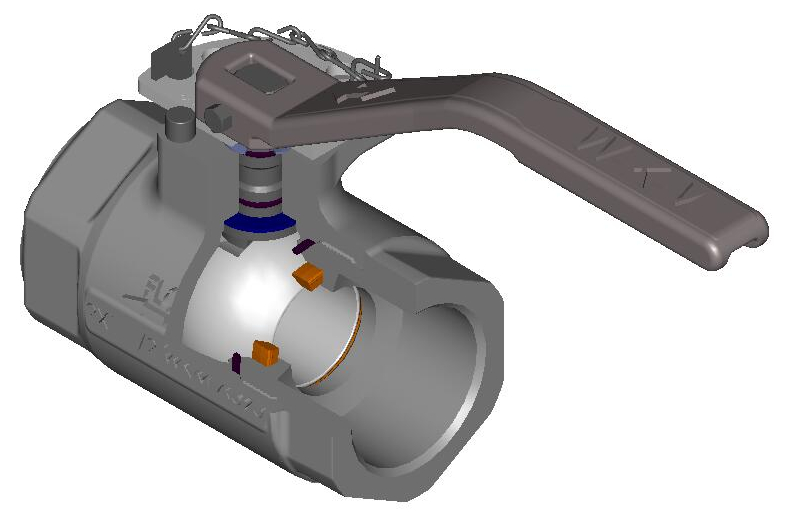

The WKM® model 210A ball valve is a two piece design with ductile iron body and tailpiece. This economical valve includes many of the premium design features found in the WKM carbon steel 310C and 310D ball valves. It is available in 1" to 4"x3" sizes. Working pressures offered are 1,000, 1,500 and 2,000 psi. Maximum pressure ratings are 2000 psi, 1" to 3"x2" valves, and 1500 psi for the 3"x3" and 4"x3" valves. This valve is primarily used in the Oilfield market, typically chosen for the following applications:

- Production wing valves on low pressure gas wells

- Production flow lines

- Production gathering systems for water, oil, and gas

- Gas blow down service

- Tank batteries for storage or production

- Frac water tanks

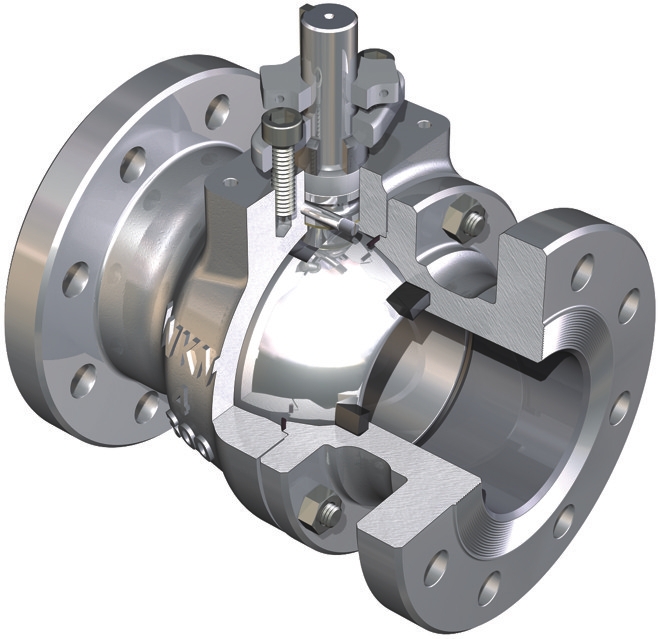

WKM® DynaSeal Model 310C 2-piece floating ball valves satisfy a wide range of applications. Available in a variety of standard and optional materials, they may be specified in sizes from 1/4" to 4" and pressure ratings of 150 and 600. Engineered for heavy duty, maintenance free performance, the DynaSeal 310C 2-piece is commonly selected for a variety of applications in virtually any industry.

Industry-recognized flanged and threaded end floating ball valves for oilfield and industrial applications with the following features built into every valve

Locking Capability is Standard

The valve can be locked in the open or closed position.

Positively Retained Stem

The stem is positively retained. It is designed to prevent stem blowout while the valve is in service.

Color-coded Working Pressures

The lock plates are color-coded so pressure ratings are quickly identified.

- 750/1000 psi: green

- 1500 psi: blue

- 2000 psi: red

Unidirectional Ball (Option)

The WKM DynaSeal 210 unidirectional valve option provides relief to valves that might have water trapped in the body cavity and then are exposed to a temporary freeze. Since this option relies on a relief hole in the ball to relieve the excess pressure, the valve is stamped with a directional flow arrow to be sure the side of the ball with the hole is installed upstream.

Fire-tested Design

The WKM DynaSeal 210 ball valves are qualified under API Standard 607. The deep-pocketed seat, locked in stem and body/tailpiece designs give this valve excellent fire-tested characteristics.

Superior Stem Journal Design Prevents Stem Seizure

The stem is designed with two internal O-ring grooves located on either side of a shallow grease groove. The top O-ring is a weather seal while the bottom one seals the stem bore against the line media. The stem gasket provides a backup seal.

The shallow groove between the O-rings provides three benefits:

- Prevents stem seizure

- Reduces torque

- Provides a space for lubricating grease applied at the factory during assembly

TFE Body Seal

A TFE body seal is positioned between the line bore and tailpiece threads, isolating the threads from the line media.

Deep Recessed Seats

The seat is recessed into a deep machined pocket, which serves to surround and protect the seat on all sides. This design eliminates cold flow into the valve conduit where it can be damaged by the action of the ball or the flow medium. The result is long and extended service life.

Seal Pin Device Provided as Standard on 750 and 1000 psi; 2”, 3” and 4” (50 mm, 80 mm and 100 mm) Reduced Port Valves

A secondary seal pin device for applying tamper detection is provided on these valves. They are a popular choice for production tank batteries where tamper detection often is required.