GAS

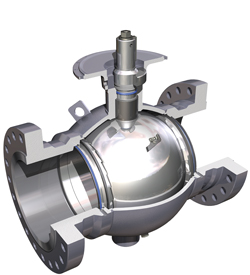

Cameron welded ball valves are renowned worldwide for dependable pipeline service. The all welded ball valve combines the strength of forged steel components with a compact light weight, spherical design. The bolted body valve is a three piece trunnion design constructed to allow field service and maintenance.

Cameron Fully Welded Ball Valves satisfy ANSI 150 through 2500 and API 2000 through 10000 standards. Made of forged steel to assure uniform fine grain structure and toughness, they may be specified in sizes from 2" to 56".

Engineered for heavy duty, maintenance-free performance, the Cameron Welded Body Ball Valve is commonly selected for a number of applications, including:

- Gas transmission

- Products pipeline

- Measurements skids

- Dehydration systems

- Gas separation systems

- Natural gas storage

- Dryer service

- NGL plants

- NGL pipeline

- Compressor stations

- CO2 services

- Offshore

- Subsea

The distinctive design of the Cameron Fully Welded Ball Valve gives it maximum strength at minimum weight as well as maximum resistance both to pipeline pressures and stresses. The compact, spherical design also eliminates body flanges, thus reducing overall size and leak paths.